Those of you who have followed my blog for the last decade or so may be shocked to read that I just sold my Bede BD-4C airplane. I am 90% delighted and only 10% sad. Yes, I will miss flying it. The BD-4C is an amazing airplane and it was everything that I wanted it […]

Airplane Wheels

I got a flat tire on my airplane and, while I was fixing it, I realized that airplane wheels are kind of odd, at least compared to car and motorcycle and bicycle wheels. So I figured I would share some photos. First of all, I had to negotiate access to the wheel with its resident […]

Tow Bar Attachment for Bede BD-4C

My FBO, St. Charles Flying Service, offers a wonderful service. They will put my airplane back in the hangar for me after fueling it. It seems like a little thing but it’s nice. There was only one tiny little detail which prevented me from taking them up on it: none of the attachments on their […]

This is What Flying is All About

I took advantage of beautiful weather yesterday to fly Caedmon and Geoff to the LSA Expo in Mount Vernon, IL. On the way, we flew over the confluence of the Mississippi and the Missouri rivers. The Mississippi is on the left; the Missouri on the right. Can you tell which one is muddier? It was […]

Cutting Aircraft Aluminum with a Hackzall

I tried all sorts of tools to cut the thicker aluminum stock while I was building my airplane. I used a band saw with a regular wood blade for most of it, finishing the rough edges with a big disk sander and then deburring with a six-inch Scotch-Brite wheel on a bench grinder. That worked […]

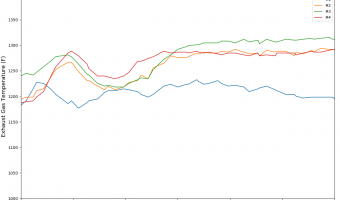

Improved Engine Cooling Baffles

When I built my Bede BD-4C, I decided to install an air plenum over the top of the engine. I built the plenum out of aluminum and was not entirely thrilled with the results. It was a lot of work and I figured that it was likely to crack. It did. But before the plenum […]

Night Currency

I went flying last night to regain my night currency so that I will be legal to fly passengers at night. Things look very different at night. It takes some extra work and practice to fly safely when there are many fewer visual cues available. The FAA Requires… A United States pilot’s license never expires. […]

Dual Alternator Failure

I chose to build a Bede BD-4C airplane in large part because it is a very simple airplane and simplicity correlates highly with reliability. Most of the time. On a recent flight with Steve, I had been proudly bragging about how I had installed dual alternators on my airplane for extra reliability. Less than 30 […]

Departing AirVenture 2019

Flying out of AirVenture is easier than flying in. It is still an adventure but, unlike arrivals, the waiting happens while sitting still on a taxiway instead of while flying at 90 knots (115 MPH). Once I had my airplane all packed up, I got help from a couple of EAA volunteers to push my […]

AirVenture Show Plane

When I planned my trip to AirVenture 2019, I never imagined that my Bede BD-4C would end up near the flight line, with all of the airplanes that are gorgeously painted and meticulously finished. N2468Z has not yet been painted. It got upholstery on the seats just a few days before AirVenture but it still […]

Flying to AirVenture 2019

I flew my Bede BD-4C airplane to AirVenture 2019, closing a seven year gap during which I drove to Oshkosh because I did not have a flying airplane. I last flew to AirVenture in 2011, just before I sold my Piper Arrow. Sunday morning, July 21, 2019 brought high clouds in the St. Louis area, […]

Flying My BD-4C from Missouri to Florida

It has been much too long since I took a small airplane on a long cross country flight. The last time was in October 2011, when I delivered my Piper Arrow to its new owner in Ohio. On June 12, 2019, I flew my Bede BD-4C from Creve Coeur, MO (1H0) to Fort Pierce, FL […]

N2468Z is Legal to Fly Anywhere and Carry Passengers

I took the last two test flights in N2468Z, my Bede BD-4C airplane, today. After landing, I made the official entry into the aircraft logbook. Having made that entry, and signed it, my airplane has completed “phase 1 flight test.” I am now free to fly it anywhere (no longer restricted to a flight test […]

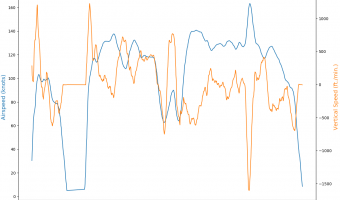

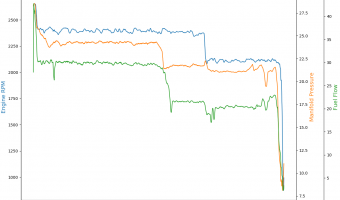

Stall Speeds and Rolling Averages

On May 12, I took my Bede BD-4C airplane up for another test flight to refine the stall speeds. I had previously determined that the slowest stall speed, with the flaps fully extended, was 61 knots. That seemed too fast and I wanted to recheck it. Here is the overview graph of airspeed and vertical […]

Takeoff and Landing Performance; Fuel Flow Tests

Last Sunday, before the high water, I did a few quick performance and fuel flow tests in my Bede BD-4C airplane. I wanted to get a rough idea of “short field performance,” how little runway is required to take off and land. I also wanted to confirm the fuel flow rates at several typical engine […]

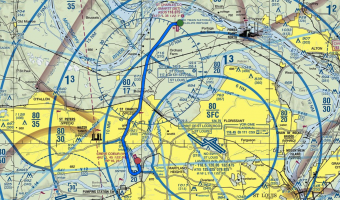

First “Cross Country”

I took N2468Z, my Bede BD-4C airplane, on its first “cross country” flight this morning, not because I wanted to, mind you, but because Mother Nature has flood waters comin’ to my hangar. I had planned to spend Saturday moving my airplane and cleaning out the hangar but the NWS updated the forecast last night. […]

Autopilot Tests

I took my Bede BD-4C airplane up for another test flight last Sunday. It was one of those gorgeous spring days with blue skies, light winds, and nice temperature—all too rare here in St. Louis. Having had a whole day of actual spring, I am anticipating sweltering summer within the week. Missouri, you see, has […]

Testing Fuel Flow, Airspeed, Endurance, and Range

I had N2468Z, my Bede BD-4C airplane, up for 1.7 hours on April 6. This flight was designed to test fuel flow and accurately measure airspeed so that I could calculate the airplane’s endurance and range, and calibrate the airspeed indicator. I flew up the Mississippi River past Quincy, IL and back. The flight went […]

Best Rate-of-Climb and Best Glide Tests

I continued testing my Bede BD-4C airplane this week. I went out one evening and began flights to determine the best rate-of-climb speed, which would allow me to determine the best angle-of-climb speed. I got to fly and see a gorgeous sunset but I ran out of time and could not complete the tests. I […]

Stalling an Airplane

Several of you have talked to me about the stall tests of my airplane so I figured that I ought to do a short video and show you what is involved. Stalls are not anywhere near as exciting as they sound, certainly nothing like the way that Hollywood depicts them. Let’s start with a tiny […]

- 1

- 2

- 3

- …

- 14

- Next Page »