Despite spending a week in tech rehearsal for Act Two Theatre’s production of Annie the Musical, I got a lot done on my Bede BD-4C airplane. First, I figured out a problem with the last pieces of the fuselage skin. Then I installed the wing tips, fabricated a couple of brackets, and installed the data plate. Hang on tight; I’ll walk you through the details.

Misfit Front Fuselage Skins

I had delayed bonding the last two pieces of the fuselage skin. They attach by the pilot’s and copilot’s feet and, without the skins in place, I have much easier access to work inside the airplane. The skins have been fabricated, fresh air vents bonded to the insides, rivet holes drilled and countersunk, and bolt holes drilled. It should have been a trivial task to double check that they fit correctly. Fortunately I doubled checked because they are nowhere near fitting properly. Here is the wide shot.

From a distance, it looks fine but here is a close up of one of the rivet holes. You can see that the hole behind the skin does not line up at all.

It took lots of fussing around until I finally figured out that the problem is that the instrument panel has insufficient support and it is sagging, pulling the window frame downward and inward. Here is a photo of the back of the instrument panel. You are looking at the back of the instrument panel in front of the pilot. On the right side of the photo, you can see the inside of the same skin pictured above.

Follow the black tube curving from the bottom center of the photo, upward and toward the right. It ends on top of a flat piece of aluminum which sticks out to the left and attaches underneath two small black boxes.

That flat piece of aluminum, just 0.063 inches thick, and it’s mate on the other side of the plane, are all that are keeping the instrument panel from falling down to the floor. There are other braces which keep the panel from wobbling but only these two support the panel’s weight.

That piece of aluminum, and the angle to which it is attached underneath the black tube, are not rigid enough for this job. The instrument panel pulls the aluminum angle inward and down, which keeps the rivet holes in the skin from aligning. Worse, it means that the panel would bounce around in turbulence and, eventually, something would break.

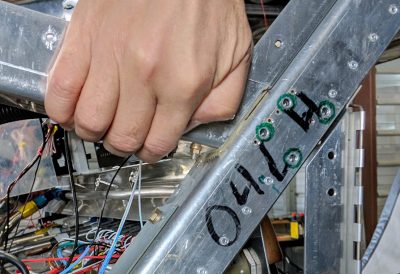

Here are a couple more photos showing the extent of the problem. I took the skin off and shot this close-up of the other side of the the same angle. Note that the bottom of the window frame angle ends near the top of the “4” in the label written on the square channel. (Click on the photo to see it larger.)

Then I grabbed the window frame and pulled it upward, so that its outer side is vertical, instead of tilted inward. I was lifting the weight of the instrument panel. You can see that the end of the window frame moves up about 1/8 inch.

The problem is not solved but at least I know what is going on and I can fix it. I will have to fashion a support which attaches to the square channel at the green, steel plate below my hand. The support will go upward to the instrument panel, transferring the weight off of the 0.063 aluminum and directly to the rigid square channel.

Fortunately, the rest of the work went much better.

Wing Tips

I installed the wing tips. I do not anticipate removing the wings until the first annual condition inspection so the wing tips ought to be here for awhile. I used stainless steel countersunk washers and countersunk screws so that all of the fasterners are nice and flush. Click on this photo so you can see the detail.

Cowling Support Brackets

Candy spent a couple of hours at the hangar with me today, helping me fabricate a pair of small brackets to support the center of the bottom cowling. This photo shows the bottom center of the firewall. The big white tube is the nose gear strut. I put one bracket on each side. Each bracket has a DZUS fastener in it. I used thin aluminum because these brackets do not support any weight; they will only need to keep the edge of the cowling from “flapping in the breeze.”

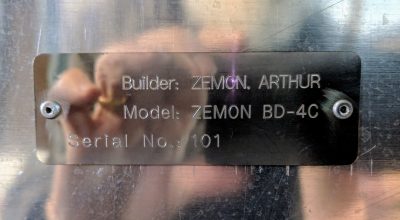

Data Plate

Last, as a bit of a celebration, I installed the data plate on the left side of the tail of the airplane.

Don’t you just love these little surprises? Good job working them out.

So a member of the Chi Psi No-Tones has figured out a way to become involved in musical theater?

(Forgive me if I misremember the name after all these years.)

You got it exactly right, Steve. What an amazing memory! 🙂

Your next build will be well informed after all these learning curves. I know, thanks to your Log, mine will be.

As always Art, a great read.

Cheers M8.

Thanks, Jim. I try not to say “next build” out loud. It’s better for my marriage. 😛