I have spent the last week making the steel frames for the doors for my BD-4C airplane. OK, let me be more precise. I spent the last week making the first frame. Having done the copilot’s door, and figured out all the hard stuff, I made the pilot’s door in few hours today. The only task remaining is to tack-weld the pieces together but, since it is now 7:00pm, I think I will write this blog post and then go watch some Netflix with my beautiful bride of 16 years and a day (yesterday was our anniversary <3 ).

Early in the door planning phase, I figured out that I wanted a 3/16 inch gap between the door and the door frame. I was in the basement using my table saw to slice up a piece of scrap wood into 3/16 shims. My old shop vac was doing its sucking thing, turning electricity into noise and wind, when all of a sudden the vacuum slowed down and then slowed down some more. I looked over at the trusty red companion and it was all blue sparks and flame inside the motor vents. Being a bright boy, I unplugged it and hauled it out to the trash, and thus ended my shim cutting for the day. It was probably time for that vacuum to die; I think I had had it since I lived in Long Beach, California in the 1980s.

The frame of the BD-4C door is made out of 4130 chromoly steel, .75x.75 square tubes with .035 wall thickness. It is strong and, for steel, pretty lightweight. Five pieces make up the outer frame, with a sixth piece running horizontally across the middle.

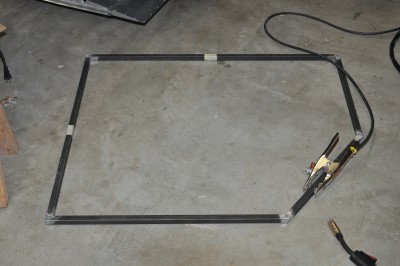

Here is a photo of the copilot’s door, with the first five pieces cut and temporarily in position to be sure that everything fits. You can click on this picture, or any other, to see a larger version.

As you can see, three of the corners are right angles. Those were easy to cut. I set my cut-off saw to 45°, touched up the resulting cuts on my sander, and everything was copacetic. The other two angles were challenges, though. I was about to buy an angle finder when I stumbled across a stone-simple way to cut the miter angles on finehomebuilding.com, Accurately Cut Miter Angles Without Using Measuring Tools. Check that page for a two-minute video of a super time (and money) saving technique. It worked perfectly for my doors. Here is one of the miters:

As I have mentioned in the past, my welding was pretty crude. I was afraid that I would burn holes in the steel tubing of the doors, just trying to tack-weld the pieces together since the tube is only .035 inches thick. Luckily, Steve at S. S. Radiator and Welding was willing to give me some pointers and boy did it help! Here is one of my tack-welded corners. I’m pretty happy with this. The trick seems to be to use a much higher wire feed speed than I had been using.

With Steve’s advice, I was able to tack-weld all five pieces without blasting any holes through the tubing at all.

Having figured out all of the tricky parts, making the five pieces of the pilot-side door went much more quickly today. Not only did I have the miter angles all figured out, but I was able to use the copilot-side door as a template instead of measuring each dimension with a ruler. Here is the result:

Tomorrow evening’s task is to tack weld the pieces of the pilot-side door together.

with all the experience you are gathering you are far exceeding the ordinary builder. Most airplanes just both together like an erector set but you have some real ingenious extra projects.

Yup 🙂 I’m getting to fabricate all sorts of stuff.

— Art Z.