I am going “off plan” for the tunnel of my Bede BD-4C airplane. The plans call for using sheet metal screws to attach the top of the tunnel to the walls. I am not a fan of sheet metal screws; they always seem to loosen and fall out. After replacing the screws a couple of times, the holes in the sheet metal get enlarged and then the screws will not fit, necessitating a move to larger screws and another cycle of falling out, replacing, and enlarging.

I decided to use U-Type Tinnerman nuts (NAS 395). For my application, the A1787-8Z-1D is just right. Since this is my first go with Tinnerman nuts, I decided to build a mock-up of the tunnel, to allow me to figure out the measurements.

I decided to use U-Type Tinnerman nuts (NAS 395). For my application, the A1787-8Z-1D is just right. Since this is my first go with Tinnerman nuts, I decided to build a mock-up of the tunnel, to allow me to figure out the measurements.

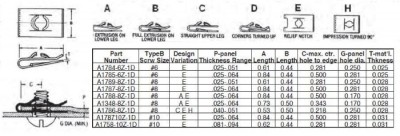

Aircraft Spruce’s catalog includes a great table which got me started on the measurements. (Click to see it larger.)

This spec table shows that the hole should be 0.500 inches from the edge of the material and that the hole should be 0.281 inches in diameter. But it does not tell me how much wider the top of the tunnel will need to be to accommodate the nuts.

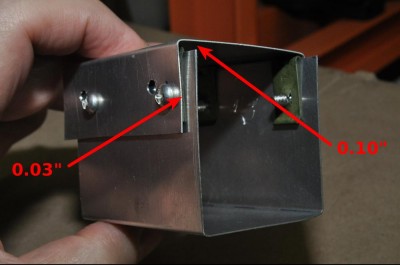

To get all of the dimensions just right, I built a little mock-up of the tunnel, 2 inches tall and 2 inches wide. When all was said and done, this is what I discovered. (Click to see either photo larger.)

The “U” of the Tinnerman nut makes the top sit 0.10 inches above the edges of the walls. The thickness of the nut adds 0.03 inches to the “thickness” of the wall. Since the tunnel top has to span two walls, and since I am not super-precise with my bending brake, I rounded up to an additional 0.10 inches in width. I.e., to span a tunnel 2.0 inches wide, I made the top 2.1 inches wide.

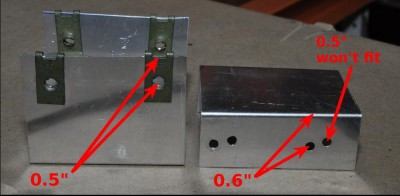

The extra 0.10 inches between the top of the walls and the top of the “U” part of the nuts means that the holes in the walls need to be 0.6 inches down, while the holes in the walls need to be only 0.5 inches down, like this

Now that I know where to drill the holes, I am ready to drill the real tunnel parts. Since the real tunnel top pieces are 42 and 52 inches long, I don’t want to mess them up. Practicing on a couple of pieces of scrap metal was well worth the time.