Over the last couple of weeks, I have finished up the mounting brackets and braces for the control stick torque tube on my Bede BD-4C. This was very fiddly slow work because it takes so long to disassemble, adjust, reassemble, and test.

I fabricated the last of the braces and drilled all of the holes, appropriately sized either for 1/8″ rivets or AN3 bolts. It does not look like much in the photo but there are 13 separate pieces, all different, holding this torque tube in position. (Click any photo to see a larger version.)

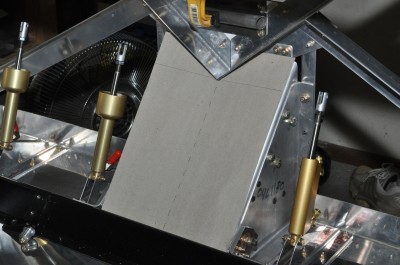

This photo is taken from the left side of the aircraft, looking into the cockpit and slightly forward. The pilot’s control stick will attach to the fork in the lower left corner of the picture; the copilot’s stick will attach to the fork in the top center of the picture.

I cut notches in the cross-fuselage brace so that the control sticks could be pushed fully forward.

It only took three cycles of

- Mark the notch

- Disassemble

- Cut the notch a little bigger

- Reassemble

- Test

to get the notch large enough so that the torque tube could rotate fully forward without hitting the brace. Though Robin Hood supervised and had a lot to say about my process, he wisely let me make (and learn from) my own mistakes. He is a gentle mentor of the highest order.

I then went through a few more cycles of disassembly, sanding down the white Micarta blocks, reassembly, and testing, to get the torque tube to rotate smoothly without binding. When that was done, I reinstalled the torque tube in the fuselage for a final test. It still rotates easily so I finally pronounce this stage done.

And I still get to remove, disassemble, reassemble, and reinstall once more: I need to get the torque tube out of the plane so that I can paint it.

With the torque tube done, it is time to start work on the tunnel which runs down the middle of the fuselage and covers up controls which run to the tail of the plane. First step was to make a cardboard template of the front of the tunnel. This covers the back of the nose gear.

Naturally, I used aviation-grade cardboard. As an aircraft kit builder, I keep a stock of it in the recycle bin, cleverly disguised as discarded cereal boxes.

Yes, you’re right. The rudder pedals have been removed from the plane, again. They were in the way of installing the front of the tunnel. In case you have not guessed, that happens a lot with planes. Put it together, take it apart, put it together again, take it apart again, and again, and again. It is kind of zen-like, peaceful, repetitive. Maybe I could write a book, Zen and the Art of Aircraft Maintenance.